2024.8.08 Knowledge

Key points on the Types of Packaging in International Shipping

There are countries, ports, and operators like Japan that handle cargo carefully and attentively, while there are also places and operators in some countries where we sometimes find disorganized and rough approaches.

When it comes to preventing cargo damage, choosing appropriate packaging for the commodities is crucial. In this blog, we'll cover the types of packaging used in international shipping and other essential information.

<To Reduce the Risk of Cargo Damage>

Suppose the shipper packs the commodities before delivering them to the designated warehouse. If so, there might be cases that the cargo might not be in a suitable condition for long-haul transportation.

International shipping packaging is not merely about wrapping the products. For commodities that cannot be lifted manually, arrangements for using forklifts or other equipment are necessary.

Moreover, in cases where transportation costs are calculated based on gross weight for air or sea consolidation shipments. The heavier the cargo, the higher the transportation cost. To reduce costs, some may apply simple packaging that may not withstand transportation.

Inadequate packaging may lead to cargo damage and pose risks such as delays in deliveries, insurance claims, and the need to re-ship replacement items, which will ultimately increase expenses.

<Types and Characteristics of Packaging>

Next, we'll introduce the types of packaging and which types of cargo they are suitable for.

・Carton

Carton packaging is suitable for small and lightweight goods or sturdy goods with low risk of damage. There are other options including reinforced cardboard or UN cartons that are used for transporting hazardous goods.

・Case

Crates made from materials like wood, steel, or plastic are suitable for packaging heavy items that cannot be carried manually or delicate equipment prone to damage.

It's important to note that when cargo cannot be carried manually, the use of pallet jacks becomes necessary.

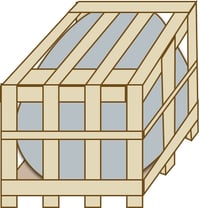

・Crate

Wooden crates with visible interiors are used for transporting machinery or equipment that doesn't require the robust protection of a fully enclosed case. Due to the lesser usage of wood compared to cases, they offer the advantage of lighter weight.

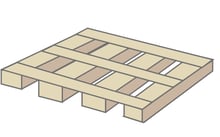

・Pallet

The flat structure is designed to fit the forks of a forklift. They can be made of wood or plastic. Commodities in the form of cartons can be stacked on top of them. They are widely used for packaging various products, including food and apparel products.

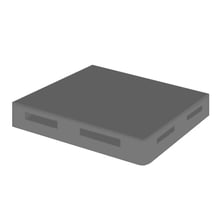

・Skid

The structure resembles a pallet but typically lacks boards on both sides. It's often used to attach directly to the bottom of heavy items for forklift handling or to stack goods, such as cartons, on top of it.

Though "pallet" and "skid" are occasionally interchanged, pallets usually feature boards on both sides, whereas skids may have boards on one side or none, serving primarily as a base for goods or forklift handling.

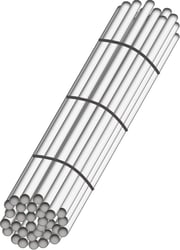

・Bundle

Cargo that is bundled and secured together is commonly used for materials like pipes or steel, which are less prone to damage and often used as raw materials for further processing.

・Bare

Refers to cargo that is not being packaged at all.

Large equipment or products that cannot be packaged due to their size will be transported in a bare state.

・Barrier Packaging

Refers to a packaging method where the product is wrapped in sheets made of aluminum to create a sealed environment. Sometimes, desiccants are added to the sealed environment. Barrier packaging is applied for products that require protection from moisture to prevent mold or rust. After sealing with a barrier, the commodity is then packaged in cases, on crates, or skids.

<Export Packaging: Heat Treatment / Fumigation Treatment>

As stipulated by the international standard ISPM No.15, 'Regulation of Wood Packaging Material in International Trade", to prevent the attachment of pests to wooden packaging materials and the introduction of pests into the importing country, appropriate measures must be taken when exporting goods.

There are two methods of treatment: Heat treatment and Methyl bromide fumigation treatment. Wood treated by either method is stamped with an approval mark as proof of disinfection."

Credit: JETRO "Trade and Investment Consultation Q&A: Fumigation Treatment of Wood Packaging Materials"

It is essential to note that wood packaging materials without the approval stamp cannot be exported. If the stamp is accidentally omitted, you'll need to either return the treated materials to the processing facility for stamp application or arrange for the processing facility to stamp the materials at your location.

<Additional key information>

・Skids

Proper orientation and positioning of skids are critical, particularly for unbalanced or irregularly shaped cargo. Take a load measuring 50cm in height and 600cm in width as an example, if the skid is aligned along the longer width and the forklift's forks cannot be inserted from the side, warehouse staff may have to insert the forklift on the other side. However, this could result in the forks reaching only a portion of the cargo, which would cause imbalance and instability during lifting.

To ensure safe cargo handling, it's essential to plan the fork positioning, especially for cargo with unusual shapes or dimensions.

・Center of Gravity (COG) Marks

Have you ever seen such marks on the cases? These are called Center of Gravity (COG) Marks, indicating where the center of gravity of the cargo is located. Typically, cargo without these marks is assumed to have its center of gravity at its center.

When the commodities are packaged in cases, the contents are not visible, making it impossible to determine their shape or whether the center of gravity is off-center. Therefore, these marks are added to packaged cases to ensure the safe handling of the cargo.

Transporters are using these marks as reference points for inserting forklift forks or lifting the cargo. In the case of skids or bare cargo, marks are drawn on the cargo diagrams/ documents to indicate the center of gravity for smooth handling.

Moreover, for heavy cargoes that require lifting, there may be marks indicating the lifting points. These marks not only indicate the center of gravity but also prevent damage to the carton when it is being lifted.

<Optimal Packaging is Essential for International Shipping>

What are your thoughts on the importance and various types of packaging?

Ensuring proper packaging is essential to minimize the risk of damage and ensure the safety of transportation.

At MOL Logistics Co., Ltd., we offer guidance and assistance on packaging needs.

Whether you're considering reassessing your current cargo packaging, requiring help with new packaging solutions, having specific concerns, or simply need more information about packaging, feel free to reach out to us!