2025.7.10 Knowledge

What Are BT-BT and FIO? Key Terms and Considerations for Breakbulk Shipping

When arranging cargo transport via breakbulk vessels, the required information differs significantly from that of container shipping. You may also encounter many unfamiliar terms during the process.

While you may rarely arrange a breakbulk shipment directly, having a basic understanding of key terms will help ensure smooth communication with your freight forwarder or shipping agent.

This article explains the essential terminology commonly used in breakbulk operations, and highlights key points to watch for when coordinating such shipments.

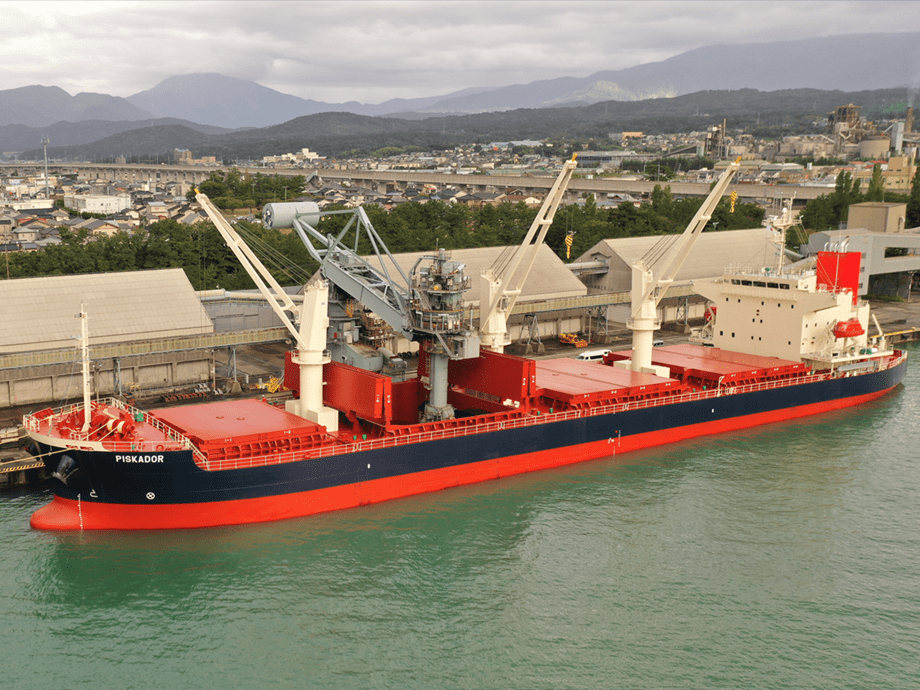

Previous article: “What is a Breakbulk Vessel? How is it Different from a Container Ship?”

<Common Terms in Breakbulk Shipping >

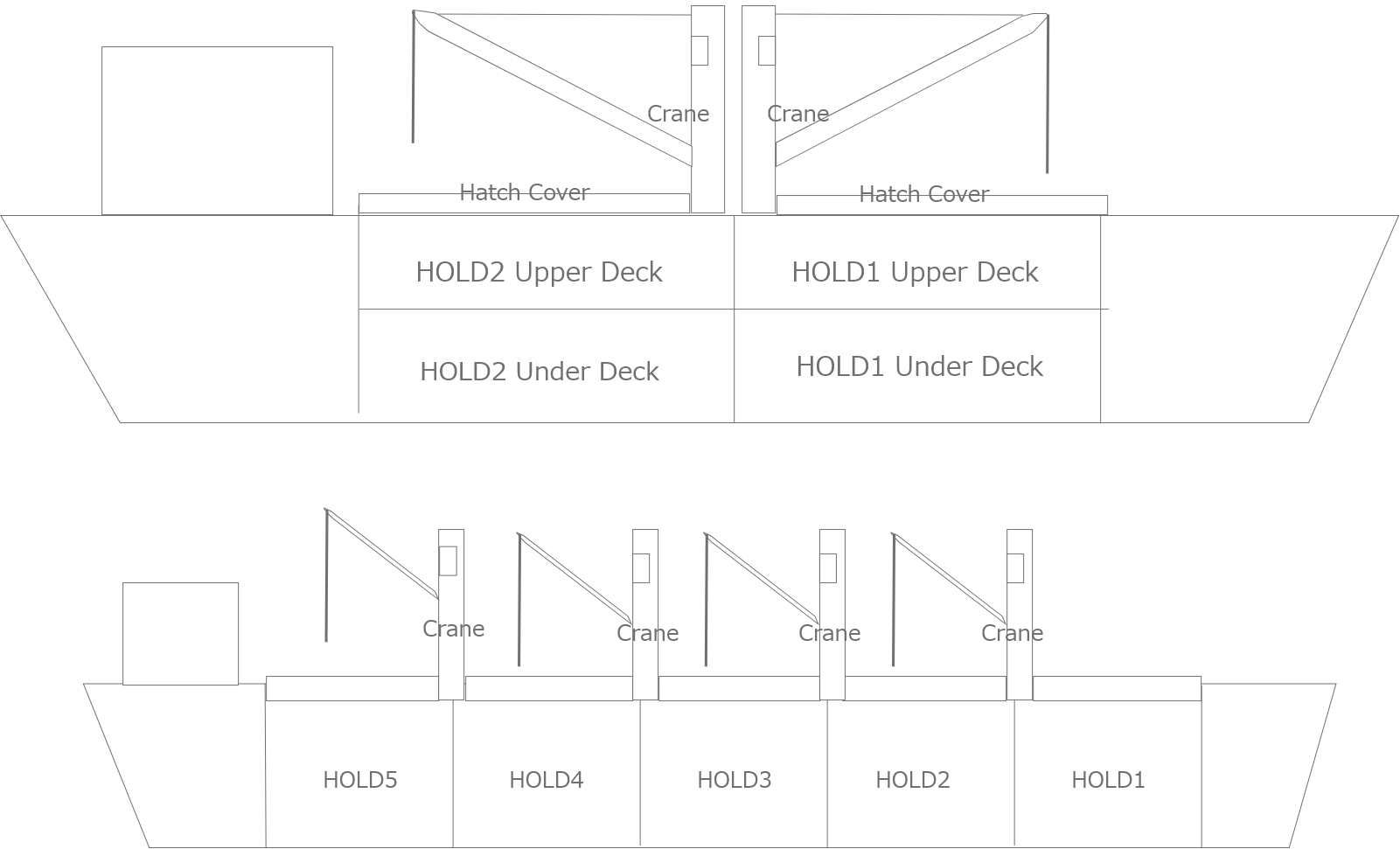

・Hatch / Hold(ホールド)

A hatch is the opening on the deck of a vessel used for loading and unloading cargo. The hatch cover is the lid that closes the hatch.

A hold refers to the cargo storage space below deck.

・Upper deck/Lower deck

These terms refer to the two cargo-carrying levels of a tweendecker, allowing for more flexible cargo stowage.

・Under deck/On deck

Under deck refers to the protected space below the hatch—safe from seawater or rain—where sensitive cargo like steel, machinery, and wood products is stored.

On deck refers to the exposed deck area above the hatch, used for oversized or water-tolerant cargo.

・FAS(Free Alongside Ship / 船側渡し条件)

One of the Incoterms 2020 rules, where the seller’s responsibility ends once the cargo is delivered alongside the ship. Delivery may be from land (by truck) or sea (by barge).

Schedules are usually discussed using terms like “Alongside [date].”

・BT-BT(Berth Term)

A freight term where the shipping line is responsible for loading/unloading and cargo securing, and these costs are included in the freight. This is a common term unless the vessel is chartered privately.

・FIO(Free-In & Free-Out) ※FI-FO

A freight term where the shipowner is not responsible for loading/unloading. These tasks and costs fall to the charterer.

・HOOK ON / HOOK OUT

Hook on refers to attaching lifting equipment (hooks, slings) to cargo.

Hook off means detaching the gear after unloading. Under BT terms, hook on is usually the shipowner's responsibility—but this can vary by country/port, so it's best to clarify during quotation.

・TRS(Terminal Receiving System)

A system where the carrier receives cargo at a designated warehouse rather than loading it directly onto the vessel. Additional charges apply for handling and transferring cargo to the berth.

・Dunnage

Materials such as wood used to secure cargo, distribute weight, and prevent damage during transport. This may or may not be included in the ocean freight cost.

・Lay/Can (LAYTIME CANCELLING)

The agreed period when a ship must be ready to load cargo. If the ship misses the cancelling date, the charterer may cancel the contract without penalty.

If the charterer isn’t ready by the laycan start date, demurrage or cancellation fees may apply.

・LAY TIME

The time allowed for loading/unloading. If operations exceed this time, demurrage fees apply. Conversely, completing early may result in dispatch payments (rebates).

・Demurrage

A penalty paid when cargo operations exceed the agreed laytime. It’s essential to prepare thoroughly to avoid delays due to issues like customs clearance.

・Stowage Plan

A layout plan showing how cargo is arranged within the ship.

・Boarding Application

If you wish to board the ship for cargo supervision, you must apply in advance with details such as name, company, and contact. Boarding may be restricted due to infection control policies.

・Stevedore

A contractor specializing in cargo handling at ports.

・Gang

A team of stevedores. One hatch typically requires one gang (10–13 people), depending on the vessel size.

・Tallyman (Checker)

Responsible for counting cargo and inspecting its condition during loading.

・Foreman

Supervises cargo operations, coordinates with the shipowner, and instructs the gangs. In some cases, forwarders may act as supervisors (SVs) on-site.

<Points to Note When Arranging Breakbulk Shipments >

・Check the Equipment

Confirm how the cargo will be loaded at the port—whether the ship’s own crane will be used or if a shore-based crane must be arranged.

If the vessel is equipped with its own crane and its specifications meet the requirements, using it is often recommended since it eliminates the need for separate crane arrangements.

However, for cargo that exceeds the lifting capacity or reach of the ship’s crane, shore-based or floating cranes will need to be arranged.

Important Considerations When Arranging Cranes

- Confirm the Crane’s Actual Capacity

Even if a crane is rated to lift up to 20 tons, that does not mean it can lift 20 tons under all conditions. You must account for:

The weight of the lifting gear (e.g., spreaders)

The reach (boom radius) from the vessel

The reduction in lifting capacity as the boom extends

The further the crane must reach, the lower its lifting capacity becomes. Always verify that the crane can safely lift your cargo under actual working conditions.

- Ensure the Required Equipment Will Be Available on the Loading Day

In some cases, stevedores own the equipment; in others, it may need to be rented from the port authority or supplied by the charterer.

If the necessary equipment is unavailable on the loading day, operations may be delayed, and demurrage charges could apply. Prepare thoroughly in advance.

Breakbulk vessel schedules frequently change due to weather or delays at previous ports, so it’s crucial to stay flexible and coordinate closely with all parties to ensure equipment is available when needed.

- Check the Condition and Durability of the Equipment

Verify the number and condition of slings, belts, shackles, and lifting devices. Ensure their durability and remaining service life are sufficient.

Damaged or miscalculated lifting gear can snap under load, leading to serious accidents. Safety checks are critical.

・Use Handling Instructions to Alert the On-site Team

Heavy and specialized cargo requires meticulous handling. Providing detailed instructions to the site—outlining the cargo’s characteristics and potential risks—can significantly reduce the chance of accidents.

Include instructions on:

Whether cargo can be stacked

Handling procedures using cranes or forklifts

Warnings about foreseeable risks

Pay particular attention to operations from lifting to stowage on board. Provide specific directions regarding lifting points, center of gravity, lift speed, and contact between the cargo and lifting gear.

・Even Liner Services May Skip Port Calls If Cargo Volume Is Low

If the total cargo volume at a given port is too small, the ship may bypass that port.

If your shipment volume is limited or delivery is time-sensitive, check in advance whether there’s a risk of port omission.

・Check Discharge Port Restrictions

Always confirm the discharge port's capabilities in advance.

Some ports cannot accommodate large vessels due to limitations in water depth, quay length, or berth strength.

Also, oversized or heavy cargo may be unmanageable at certain ports.

If you’re chartering a breakbulk vessel, it’s essential to confirm the discharge port’s conditions and consult with the carrier ahead of time.

<Looking to Transport Heavy Equipment or Project Cargo? Contact MOL Logistics >

Project cargo transport demands strict time management and careful coordination of supporting activities.

At MOL Logistics, we have a proven track record and deep expertise in handling various types of heavy and project cargo. We work closely with other MOL Group companies that specialize in different areas, offering comprehensive solutions for:

Facility relocations

Plant and infrastructure projects in emerging markets

Complex transport challenges worldwide

View case studies here: https://www.mol-logistics-group.com/en/purpose/cargo/

Even if your cargo has been declined by other forwarders, we may be able to transport it.

Please feel free to contact us—we’d be happy to help.